Die Buying Guide

May 16th 2025

For those just starting out, knowing the difference between Clicker Dies and Steel Rule Dies can be confusing. Each type serves different purposes and is better suited for specific materials and applications. In this guide, we'll walk you through the key features and capabilities of both die types to help you make the right choice for your project.

Comparison Table

| Feature | Clicker Die | Steel Rule Die |

| Height | 1.25" Tall | 0.937" Tall |

| Base Construction | Solid Metal | Wood or Plastic |

| Machine Compatability | 7 Ton & 15 Ton Clickers | 7 Ton Clicker, 15 Ton Clicker & Roller Press |

| Cuts Multiple Cavities | Yes | Yes |

| Food Grade Option | No | Yes |

Die Type Overview

Clicker Die

Much like a heavy-duty cookie cutter, clicker dies provide clean consistent cuts for a wide range of materials like leather, plastic, rubber, cardstock and more.

We can also make custom clicker dies based on your unique design and project requirements.

Key Specs

- Height: 1.25" Tall

- Material feeds through the die when cutting, allowing you to cut multiple layers at once

- Can cut multiple cavities

- Solid metal construction

- Cuts leather, plastic, rubber, cardstock, paper, foam, etc.

- Machine Compatibility: 7 Ton & 15 Ton Clickers

Best Applications:

- Cutting thicker, heavier materials like leather

- High Volume Production runs

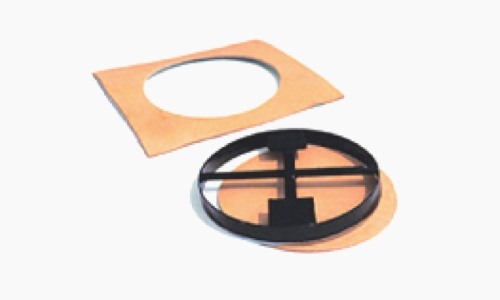

Steel Rule Die

Steel rule dies are made by bending sharp steel blades into precise shapes and embedding them in a wooden or plastic base. During cutting, the die presses the blade into the material against a flat surface, and the ejection foam helps push the cut material out of the die.

Key Specs

- Height: 0.937" Tall

- Wood or plastic base construction

- Food grade options available

- Includes ejection foam

- Compatible with all our Machines (7 Ton, 15 Ton Clickers & Roller Press)

Best Applications

- Cutting thinner materials like plastic, fabric, or printed materials

- Projects requiring food-grade compliance

Still Not Sure?

Need help deciding which die is right for your project? Give us a call and we'd be happy to talk about your project!